Electrical Thermal Imaging Boosts Electrical Functionality

If you work in a commercial facility that depends on the functioning of electrical equipment, you know the importance of keeping everything in working order. Something can go wrong too easily and quietly, leaving you with a major loss of productivity to deal with, as well as hundreds or thousands of dollars in repair costs. Did you know there’s an easy way to prevent this kind of catastrophe in your workplace? It comes in the form of electrical thermal imaging and can save you and your facility hundreds thousands of dollars potentially spent on repairs.

How Do Infrared Scans Work?

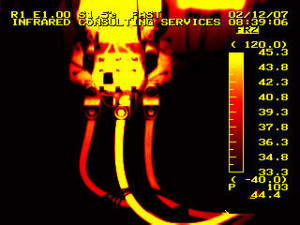

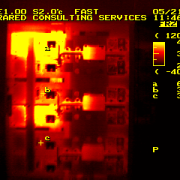

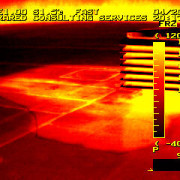

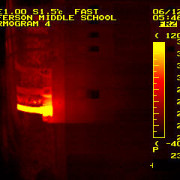

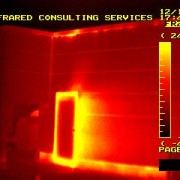

Infrared scanning, otherwise known as thermographic imaging, is meant to help detect problems in electrical equipment and other components and areas of a building that are otherwise undetectable by the average human senses. When you request an infrared scan, you’ll be hiring someone to take thermal imagery of your machinery for the sake of spotting any potential issues within them. These pictures are monochromatic and are meant to read the temperature given off by the depicted equipment. The hotter an object is, the stronger the variance from dark to light will be. This will be yours and your inspector’s first clue to any signs of trouble.

What Can Thermographic Imaging Tell Me About My Equipment?

All functioning electrical equipment conducts heat as it operates. However, it is beyond our senses to determine how much or how little heat a piece of equipment is giving off. This is where electrical testing and inspection comes in. The first sign of trouble in any electrical device is giving off far more heat than it should. If your equipment is escalating to much higher temperatures than normal, you likely have a serious problem waiting in the wings. The devices used during an infrared scan will be able to easily detect how high a temperature your facility’s equipment is reaching and provide you with a thermogram. The professional in charge of administering your scan will also be able to give you advice on the next steps you should take to resolve the problem.

Why Is This Important?

It’s always better to solve problems before they start, especially when you work in a commercial facility where valuable production time and funds are on the line. With the help of electrical thermal imaging, you have the ability to take care of any issues with your equipment before they escalate into something worse. This will also help to keep your facility as stable as possible by making sure everything is in working order and enabling you to take action with malfunctioning equipment early. If you decide to take up having routine inspections performed, you will then have a method of normal maintenance that will allow you to take care of problems even more easily.

We hope you will consider taking up this valuable preventive measure. If you have any questions or concerns about infrared inspections, feel free to contact us for more information.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.