Infrared testing, also referred to as thermography testing, has emerged as one of the most powerful diagnostic technologies in the fields of facilities management and building systems. We use our infrared surveys to detect, document and analyze anomalies in the temperature of building envelopes, roofs, electrical systems, mechanical systems and other structures.

Our services will help you locate and rectify costly and potentially dangerous problems that are otherwise invisible. We invite you to contact us today for all your Infrared Thermography Testing.

SERVICES OFFERED BY ICS:

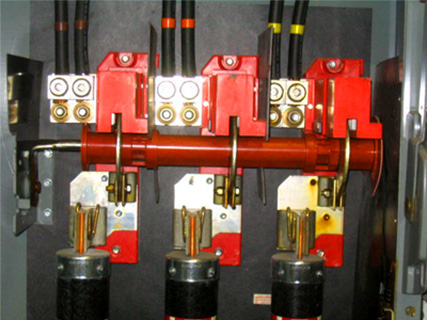

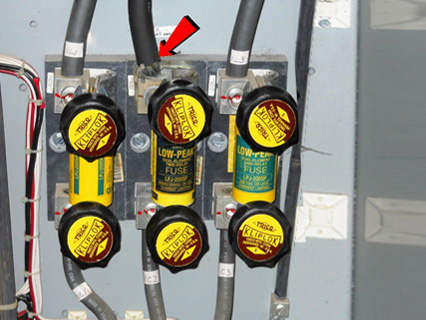

INFRARED ELECTRICAL SYSTEMS SURVEY: The infrared electrical systems survey is typically conducted on an annual basis as part of a regular preventive maintenance program. The infrared electrical testing allows for inspection of a large amount of electrical equipment in a short time as opposed to the alternative method of physically inspecting and tightening electrical components. The infrared electrical systems survey locates faulty electrical items not generally found during a physical inspection. Learn More

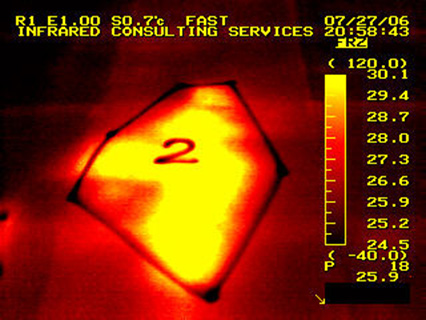

INFRARED ROOF MOISTURE SURVEY: The infrared roof moisture survey is used world-wide by building managers, facility managers, property managers, plant engineers and government agencies to accurately locate and quantify moisture trapped within commercial roofing assemblies. The infrared detection technique can be used effectively on virtually all types of low slope roofing systems. Infrared thermography is a proven scientific method for evaluating roofing condition and locating hard to locate roof moisture problem areas. Our professional infrared thermography roof inspections provide the in-depth, unbiased data that owners and property managers need to protect their costly roof systems. Learn More

INFRARED ROOF EVALUATION SURVEY: Infrared Consulting Services, Inc. Roof Evaluation Survey and Visual Roof Inspection Report provides a complete documented roof evaluation of the existing condition of your roofing systems. During the day, the sun radiates energy onto the commercial roof and into the roof substrate. In the evening, the roof radiates the heat back into the atmosphere. This process is called radiational cooling. Areas of the commercial roof that are of a higher mass (wet) retain this heat much longer than that of the lower mass (dry) areas of the roof. Infrared imagers can detect the heat and “see” the warmer, higher mass areas, during the occurrence of uneven heat dissipation from the roof. This is an ideal way to pinpoint what areas of the roof are retaining moisture which can lead to future problems. Learn More

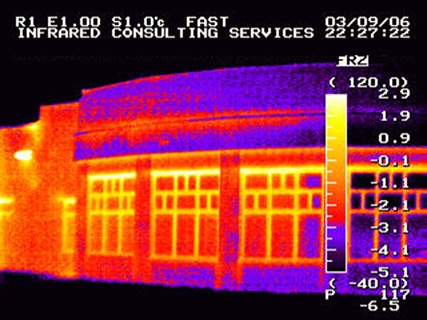

INFRARED BUILDING ENVELOPE PERFORMANCE SURVEY: The Infrared Building Envelope Performance Survey or Inspection of the building envelope detects and records the thermal performance of the wall and window assemblies. This Infrared Building Envelope Survey provides information on air infiltration, exfiltration, moisture laden insulation, insulation voids and moisture within the wall assembly. An Infrared Building Envelope Survey or Inspection should be conducted before acquiring real property, before final payment to the building contractor for new construction and as part of your building’s energy conservation program. Learn More

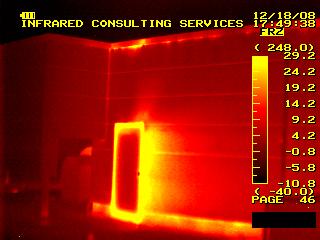

INFRARED WALL MOISTURE SURVEY: An Infrared Wall Moisture Survey or Inspection provides you with the proper information and documentation to evaluate your wall moisture condition. Wall moisture in building materials can destroy structural integrity as well as harbor mold and insect infestations. Long term water infiltration can cause catastrophic damage if not properly pinpointed and repaired. Infrared thermography is by far the most reliable method for identifying water loss or water intrusion. Traditional methods of photographs and water moisture meters do not always reveal all of the damage. Infrared cameras used in Infrared Wall Moisture Survey or Inspection can distinguish between wet and dry by measuring the thermal variations of wet materials and can provide a clear picture of moisture damage along walls. Learn More

BASELINE INFRARED SURVEY: If you are an investor, property owner or a facility manager who needs an accurate assessment of the condition and systems performance of a building, Infrared Consulting Services will conduct a thorough, baseline evaluation of temperature signatures during normal operating conditions. We use this Baseline Infrared Surveys data for comparison during real time or periodic inspections to detect thermal differences that can point to hidden problems. Baseline Infrared Surveys as a preventative or predictive evaluation is critical to maintaining all types of structures and avoiding costly repairs. Learn More

HIGH VOLTAGE ELECTRICAL INFRARED SURVEY: Electric Utility/Power companies are increasing their usage of High Voltage Electrical Infrared Surveys to promote safety and reliability of their overall power systems. We have found that temperatures alone cannot be used to determine if high voltage equipment is likely to fail. The accurate evaluation of a distribution line or substation, depends mostly on the knowledge of the person performing the High Voltage Electrical Infrared Surveys inspection. Through years of proven experience, the consultants at ICS have an in-depth and comprehensive knowledge of high voltage electrical systems as well as all of the safety processes required to properly work in a high voltage environment. Learn More

INFRARED MECHANICAL SYSTEMS SURVEY: An ICS Infrared Mechanical Systems Survey or Inspection provides the facts regarding the condition of boiler jackets, piping and refractory linings. A survey of motor bearings, couplings and other operating equipment provides information on current operations and locates overheating mechanical components. Infrared Mechanical Inspection Surveys are conducted on ductwork, and piping insulation and on certain types of steam traps to identify leakage and wet or damaged insulation. Learn More

INFRARED STEAM UTILITIES SURVEY: An Infrared Steam Utilities Survey or Inspection of radiant panels provides information on leaks, blockages and other malfunctions in sub-surface radiant panels and piping. The Infrared Steam Utilities Survey or Inspection distinctly locates the radiant piping to prevent cutting or drilling through the pipes during repair and remodeling projects. Infrared Steam Utilities Survey or Inspection are also used to locate leaks and other malfunctions in buried steam or hot water lines. In working steam systems, improper steam or heat distribution is a sign of costly expenditures and mechanical trouble. Any one of the above problems can dramatically reduce the fuel efficiency of the entire steam system and lead to costly or even catastrophic failures. Learn More

BOILER AND REFRACTORY INFRARED SURVEY: An infrared survey of boilers, refractory systems and other heating units provides information on leaks, blockages and other malfunctions in sub-surface manifolds and piping. The Boiler and Refractory Infrared Survey distinctly locates the radiant piping to prevent cutting or drilling through the pipes during repair and remodeling projects. Boiler and Refractory Infrared Surveys are also used to locate leaks and other malfunctions in buried steam or hot water lines. Boilers are good infrared testing subject since boilers are a source of thermal energy. External infrared scans of refractory, piping and doors are all common Boiler and Refractory Infrared Survey applications. Learn More

Thank you for your interest in ICS Infrared Consulting Services, Inc. We welcome your inquiry about infrared surveys, infrared inspections, infrared testing services. Please contact us directly by clicking here. We serve customers nationwide.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.