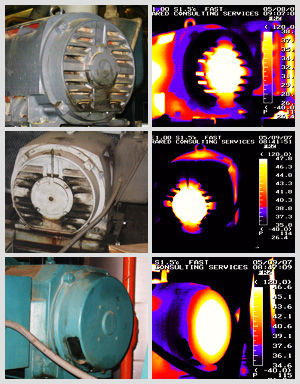

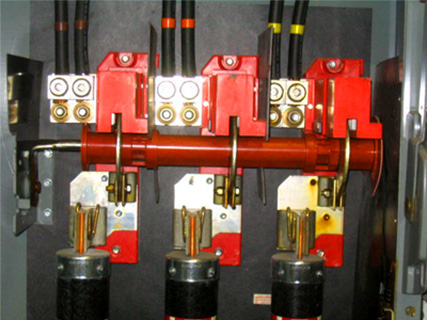

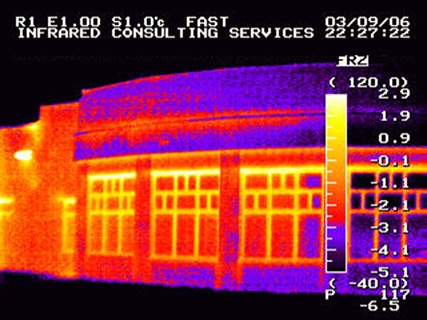

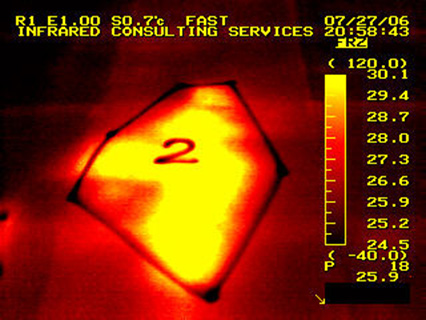

An ICS infrared mechanical systems survey or inspection provides the facts regarding the condition of boiler jackets, piping and refractory linings. A survey of motor bearings, couplings and other operating equipment provides information on current operations and locates overheating mechanical components.

An ICS infrared mechanical systems survey or inspection provides the facts regarding the condition of boiler jackets, piping and refractory linings. A survey of motor bearings, couplings and other operating equipment provides information on current operations and locates overheating mechanical components.

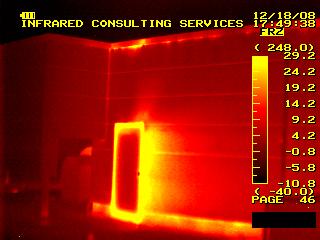

Infrared Mechanical Inspection Surveys are conducted on ductwork, and piping insulation and on certain types of steam traps to identify leakage and wet or damaged insulation.

The ICS Infrared Mechanical Inspection Surveys are applicable to LPG/LNG storage tanks, walk-in coolers/freezers and process piping. A properly conducted Infrared Mechanical Inspection will enhance your organization’s predictive maintenance policies by pinpointing trouble spots and defective areas. In addition, regularly scheduled Infrared Mechanical Inspection Surveys can be utilized to predict future maintenance schedules. Infrared Mechanical Inspection Surveys can also help predict or plan for corresponding maintenance budgets.

And because infrared thermography testing is non-contact and nondestructive testing (NDT), there is no need to interrupt system production or plan for costly system shutdowns. Our experienced ICS Thermographers inspect your mechanical equipment under normal loads and operating conditions. By performing an infrared scan of your mechanical system in ‘real time’ our infrared mechanical inspection can help you understand the practical impacts of emerging or existing mechanical component problems.

Thank you for your interest in ICS Infrared Consulting Services, Inc. We welcome your inquiry about infrared mechanical surveys, infrared mechanical inspections or infrared mechanical testing services. Please contact us directly by clicking here. We serve customers nationwide.

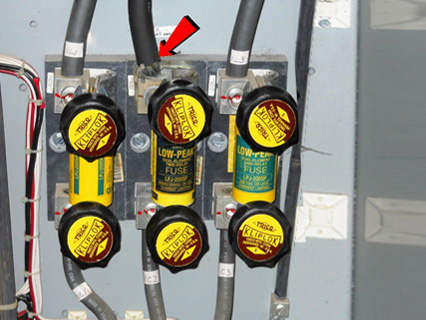

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.