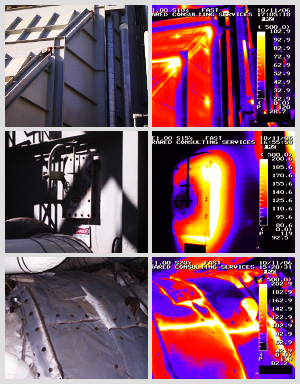

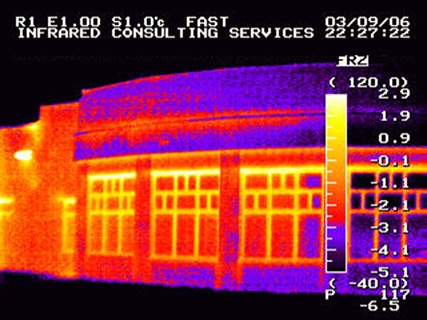

An infrared survey of boilers, refractory systems and other heating units provides information on leaks, blockages and other malfunctions in sub-surface manifolds and piping.

An infrared survey of boilers, refractory systems and other heating units provides information on leaks, blockages and other malfunctions in sub-surface manifolds and piping.

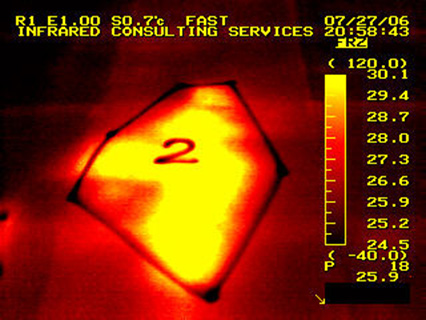

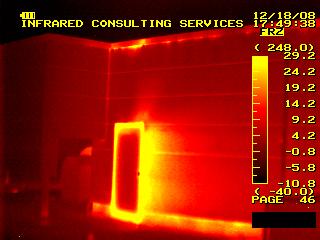

The Boiler and Refractory Infrared Survey distinctly locates the radiant piping to prevent cutting or drilling through the pipes during repair and remodeling projects. Boiler and Refractory Infrared Surveys are also used to locate leaks and other malfunctions in buried steam or hot water lines. Boilers are good infrared testing subject since boilers are a source of thermal energy. External infrared scans of refractory, piping and doors are all common Boiler and Refractory Infrared Survey applications.

Boiler and Refractory Infrared Survey / Conditions Detected

- Boilers/FurnacesRefractory/Insulation breakdown detected through a Boiler and Refractory Infrared Survey

- Hot gas leaks detected through a Boiler and Refractory Infrared Survey

- Wasted energy detected through a Boiler and Refractory Infrared Survey

And because infrared thermography testing is non-contact and nondestructive testing (NDT), there is no need to interrupt system production or plan for costly system shutdowns. Our experienced ICS Thermographers inspect your boiler and refractory equipment under normal loads and operating conditions. By performing an infrared scan of your boiler and refractory system in ‘real time’ our infrared boiler and refractory survey or inspection can help you understand the practical impacts of emerging or existing boiler and refractory component problems.

Thank you for your interest in ICS Infrared Consulting Services, Inc. We welcome your inquiry about infrared boiler and refractory survey, infrared boiler and refractory inspections or infrared boiler and refractory testing services. Please contact us directly by clicking here. We serve customers nationwide.

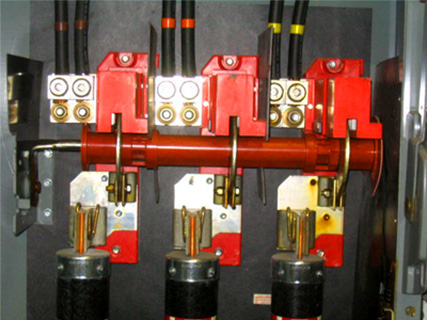

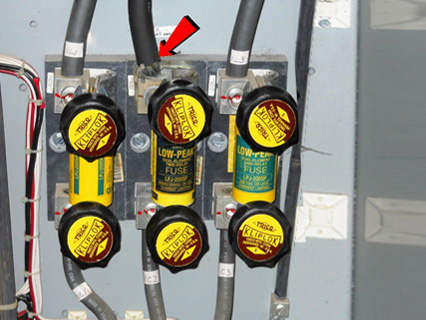

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.