Why Do I Need Infrared Testing for My Manufacturing Facility?

Infrared testing can help manufacturing plants.

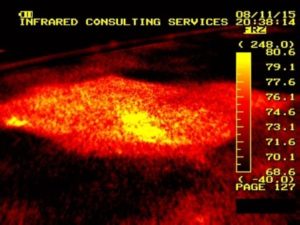

A thermal imaging survey can reveal problems.

If you’re in the manufacturing business, you may have heard of infrared testing, but haven’t used it for a number of reasons. Maybe you aren’t sure of all the benefits, or you haven’t had time to make the change from traditional inspections to infrared testing. Whatever your reasons, there are many more benefits to consider when hiring an infrared testing service for your commercial facility.

What Does Infrared Testing Do?

Certified Thermographers conduct a thermal imaging survey on your equipment to scan it for any potential problems. They will use their own equipment to record yours photographically. This photograph is monochromatic, and the intensity of the shades correspond with the specific temperatures of your equipment. When a piece of equipment begins to malfunction, the first sign is usually a spike in temperature that is often undetectable otherwise. This sudden and severe rise in temperature can signal any number of problems, including:

- Faulty components

- Poor internal connectivity

- Imbalances

- Exposed circuitry

- Energy overload

No matter the source of a problem, too much heat coming from a device is often the first and biggest sign complete failure looms in the future. This can occur in any piece of equipment, regardless of age.

How Does Infrared Testing Solve My Problems?

- Problems are Identified Early – By hiring an inspection professional to take a look at your equipment, they can easily pinpoint problems you may be experiencing. Best of all, these inspections can detect problems before they truly start, making them an excellent preventive tool. This allows you to catch problems before they can unfold into something more severe, which can save you lost productivity and costly repairs down the road.

- Machinery is Maintained More Efficiently – By allowing you to take care of the problem early, you will be eliminating the steep costs associated with repairs, which can add up to thousands of dollars. You will also be avoiding downtime within your facility, which means you won’t be losing valuable productivity. Also, your machinery will last much longer.

- Production Won’t be Halted – Another benefit comes in the form of how these inspections are performed. Electrical thermal imaging is not invasive. Traditional methods may halt your production for several hours but your team will be able to carry on a normal work day while the infrared testing takes place. This means there will be no interruption in workflow for your daily operations and you will be able to review the results at your convenience.

For an easier and more cost-efficient option for your commercial inspection, infrared testing could be the best choice for your manufacturing company. For more information on how this important preventive testing measure can ensure maximum productivity, contact us.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.