Cost of Electrical Systems Fire (and How to Prevent Them)

Hundreds of millions of dollars are spent every year in property damage as a result of fires in industrial environments. These fires can be caused by a number of factors, but one thing they all have in common is they can be prevented. It’s easy to understand the benefits of infrared inspection for companies, especially when used as a disaster prevention tool.

The scary thing about electrical systems fires is you may not even know something is wrong until it’s too late. By incorporating thermographic scanning into your regular maintenance budget, you’ll be able to put your company in a safer spot.

Causes of Electrical Systems Fires

Electrical equipment is going to be hot in most cases. Fires can occur when dust, dirt or grease is covering the equipment. Those particles provide fuel for a fire to continue burning, rather than being short-lived if the equipment were clean. Other causes of electrical fires include:

- Overloaded circuits

- Exposed or damaged wiring

- Overloaded outlets

- Worn extension cords

- Static discharge

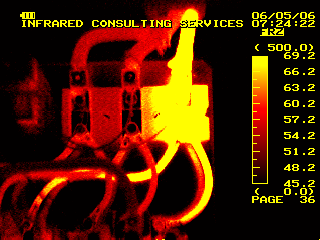

With the high-paced work occurring in industrial workplaces, it can be difficult to spot a potential electrical issue. However, all it takes is a little spark from one of these components to cause a potentially devastating fire. That’s why many companies are leaning on IR thermography to identify any possible issues so they can be fixed before a disaster occurs.

Preventing Electrical Systems Fires With Thermographic Scanning

It’s obvious how to avoid fires started by some of the most common causes, like replacing damaged wires or extension cords. However, these are just temporary fixes, for the most part. Instead, the best way to prevent electrical systems fires in your workplace is to incorporate regular thermographic scanning into your schedule.

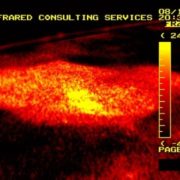

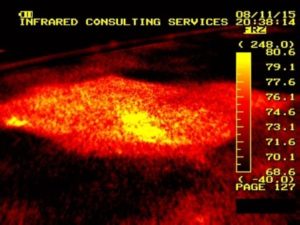

With a thermal imaging survey, you don’t even have to shut down your operations most of the time. A thermographer can come to your workplace and give you a comprehensive view of what may need to be fixed or replaced. Infrared thermography detects heat and moisture and is clearly identified on the survey. When these spots show up, it’s a clear indication that something isn’t how it should be and needs immediate attention.

Have a Plan in Place

The great thing about IR thermography is companies are able to detect problems they didn’t even know they had. This is especially important when it comes to electrical equipment. Have a plan in place to have a thermal imaging survey conducted quarterly, or at least a couple times each year.

Not only will these surveys create a safer work environment, but they could save your company thousands, if not millions, of dollars by avoiding potentially devastating fires. A regular survey, along with general maintenance and awareness on a daily basis, will go a long way in ensuring your company doesn’t have to deal with an electrical fire.

To learn more about the technicalities of infrared thermography, or to schedule your next survey, be sure to contact us.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.