Thermographic Scanning Means Accurate Inspections

It’s always better to be safe than sorry, especially when precious time and money are on the line. When it comes to the efficiency of your manufacturing plant, you want to be especially safe. Even the smallest malfunction can cost hundreds or thousands in repairs, as well as time that could be better used on industrial work, meaning more money lost. Electrical thermography is perhaps the best and safest type of preventive measure available in this day and age. It is performed in countless factories across the country.

What Is Electrical Thermography?

Electrical thermography is also known as infrared scanning or thermographic scanning. It is a means of detecting the temperature in electrical systems. A sudden or severe rise in temperature can be one of the first signs of malfunction in a piece of equipment and, when detected, can often lead to the prevention of these problems before they manifest into something worse. You can therefore use the data collected from a thermographic scan to repair any problems with your manufacturing equipment while they are still small. This means considerable savings for your company in terms of finances and production time. The cost of a thermography inspection is ultimately much better and more worthwhile than the cost of the potentially extensive repairs you’ll have to seek out if you let your machinery run to the point of breaking down.

Thermographic scanning can find problems before they become serious.

How Are Thermographic Scans Conducted?

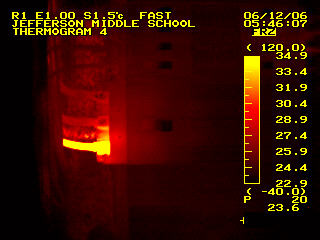

When a certified thermographer arrives at your facility to conduct the reading, they will do so with equipment designed to detect infrared signals, which are indicated by colored signals that cannot be traced with average human sight. Readings range from red to yellow by the severity of heat. These inspections can take place outdoors or indoors, depending on the location of your equipment.

Thermographers check everything from the main switchgear, plant electrical distribution down to lighting panels and safety switches for hot spots and overloads. Should any problems be detected, your hired thermographer will give you a report on their discoveries and make suggestions on how to get them repaired before they worsen and lead to complete malfunction.

Consider Infrared Consulting Services, Inc. for your next thermography inspection. We employ only the most qualified professionals to perform your readings and offer you their expert reports and advice. Our readings are always exhaustive and our inspection equipment is kept up-to-date to ensure our readings are as accurate as possible. To learn more about our services or schedule a reading for your facility, contact us.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.