How Infrared Consulting Services Can Help Improve Your Motor Systems

Having a motor maintenance program in place is one of the most overlooked aspects in companies today. By doing a circuit analysis and thermography inspection, you can predict when to perform maintenance rather than waiting until it’s too late. Many people underestimate the value of infrared testing. However, the cost savings in the long run are significant enough to give infrared testing a serious look. Here are some ways infrared services can help improve your motor systems.

Identify Any Potential Repairs Needed

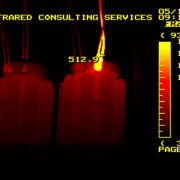

Infrared problem prevention methods will provide you with results you wouldn’t otherwise see. It’s difficult for anyone to see or feel when the temperature of any part of a motor is warmer or cooler than the other. With infrared testing, you can easily identify hot spots, which could cause problems in the short-term or long-term. Performing a test to identify potential repairs before a problem occurs is a big cost saver.

Makes Motors More Reliable

Any infrared consulting services will look at your motor from the standpoint it should be running perfectly. It’s much easier to diagnose a problem if you are looking at the motor in general, rather than just a specific component or two. When you have a professional do routine infrared testing on your motors, they will be able to compare how the motor looked the previous time versus during the current test. As long as routine testing is completed, you’ll have a better chance of having a more reliable and efficient motor.

Predictive Maintenance

When you do a thermography inspection, you are essentially conducting preventive maintenance. Whether or not you think there is a current issue with a motor, it’s still a good idea to get infrared testing done regularly. Since it is impossible to detect some problems with the naked eye, IR testing can help you see a potential problem before it escalates and becomes costly.

Infrared testing is an essential part of any predictive maintenance program for motors. When it’s completed correctly and routinely, companies will experience much lower maintenance costs, as well as higher productivity, more reliability and increased uptime. Without a solid predictive maintenance program, you’re leaving the health of your motor to chance. The money you spend for routine motor maintenance upfront will pay for itself in the long run.

Many companies are beginning to see the benefits of having an infrared problem prevention program in place. Our consultants at Infrared Consulting Services can identify problems at any workplace, even if there doesn’t appear to be an issue at all. If you need to schedule an infrared test for your motors, contact us today to set up an appointment or to get more information about the procedure.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.