Five Least-Expected Places for Air Leaks to Occur

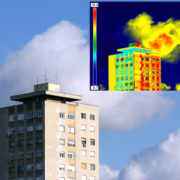

Air leaks are a common problem, but few people investigate them before it’s too late. This shouldn’t be the case for anyone, especially if they’re involved in a commercial facility where efficiency is key. Thermal imaging services, as well as your own vigilance, can easily help tackle this problem. The first element of prevention is knowing where to look! Here are five rarely suspected problem spots you may want to watch out for in your facility.

1. Basements

If your facility has a basement, this may be a good place to check. This is one of the most likely areas of a building to lack proper insulation, which quickly leads to circulation issues. You should know the amount of insulation and similar properties within your facility’s basement. If it isn’t at the proper level, you should anticipate some form of leaking and invest in taking care of the insulation as soon as possible. If you aren’t sure how to check for leaks, a thermal imagining inspection is a great way to ensure your basement is air tight.

2. Ventilation

Proper air vents and other similar mechanisms are highly important to the maintenance of a commercial facility. Temperatures can easily skyrocket in these structures, making it vital to have decent circulation. You’ll want to run maintenance on your ventilation occasionally to make sure they’re functioning properly. Thermal imaging services can help you detect improper ventilation in your structure. Malfunctioning vents are a surefire sign of unwanted leakage. The best ventilation systems typically have covers with magnetic and detachable properties, as well as insulation padding.

3. Air Ducts

Air ducts are just as likely as vents to have some sort of leak slipping through them. Be sure to check these at the same time you check your vents, especially if your facility relies on air conditioning for daily productivity. You don’t want the comfortable and cool air to slip right out where it shouldn’t be. Luckily, with the help of a thermal imaging inspection, you can easily find out where the problem areas are!

4. Overhead Lights

People rarely suspect their overhead lighting of being leaky and inefficient. In fact, as long as the lights are functioning, we assume they’re working at 100 percent! This actually may not be the case. Certain types of overhead lights, such as recessed lighting, rely on insulation to remain functional and safe. Be sure to check whether your ceiling lights need this type of preparation and whether it is in place. If not, know this poses a risk to your facility and employees and should be addressed soon.

5. Electrical Sockets

This is yet another quite common, but typically unheeded, source of energy leaks. It’s also the hardest to detect. To pick up on the efficiency of your commercial facility’s electrical sockets, you need to rely on a thermal imaging survey to read the output of your sockets and determine whether they’re at a normal rate. Without it, you could be negatively impacting the performance of your equipment and reducing productivity.

While these aren’t the only areas of your facility susceptible to leaks, they are the most common ones that should be inspected. Contact us to learn about other preventive measures and how our thermal imaging services can help!

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.