Are Infrared Windows the Thing of the Future?

Anyone who deals with maintaining electrical systems has likely heard of infrared windows. However, since these windows aren’t widely used, some professionals don’t know much about them. As the world of infrared detection technology continues to evolve, the use of infrared windows is expected to become more popular. These windows allow thermographic imaging professionals to do their jobs more efficiently, accurately and also save businesses money on their inspections. Here are some of the main reasons why infrared windows may be the thing of the future.

How Infrared Windows Work

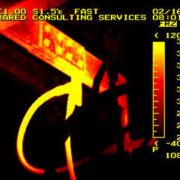

Most electrical components are covered by metal or another solid material. This presents a challenge for infrared inspection services, since they need a clear line of sight in order to effectively use their equipment. These covers are necessary from a business safety standpoint, but they also come with great risks to thermographers during the infrared scan.

Infrared windows are known as the solution to this problem. The thermographers will no longer have to spend time removing panels and covers and putting them back on afterward. The infrared window has either a plastic or metal frame and supports an infrared transmissive optic, with a cover to protect the optic when it’s not needed.

Placement of Infrared Windows

It’s important for all electrical enclosures to have an infrared window. When infrared inspection services come into a business to conduct a survey, they need to have access to all equipment. Having an infrared window installed on each of the enclosures will allow the thermographer to get the thermal images they need quickly so no time will be wasted.

However, installing infrared windows isn’t cheap, and the cost can add up depending on how many electrical enclosures you have. If your business is forced to limit the amount of infrared windows you can install, choose the enclosures that are difficult to open, have different safety hazards and need frequent inspections.

Benefits of Infrared Windows to Businesses

It may seem like infrared windows are only beneficial to infrared thermographers. That is true from a functionality standpoint, but businesses can also benefit from them. If your entire shop or workplace has infrared windows on each electrical enclosure, you could reduce the time spent on your infrared inspection significantly.

One of the main reasons why a thermographic imaging inspection takes so long is because the thermographer has to remove covers in order to get a clear view of the equipment to inspect. The quicker the process takes, the more money a business saves. Plus, the accuracy is going to be much higher with each inspection since there are no obstructions with the infrared windows.

Infrared Consulting Services has over 30 years of experience in the industry and knows exactly how to help your business save time and money. Be sure to contact us to learn more about infrared windows and to set up an appointment for your infrared testing needs.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

By detecting problems before they occur and by pin-pointing exactly where problems might exist, Infrared Thermographic Testing has many benefits.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Learn more about our wide range of non-invasive, non-destructive inspection & testing services and if they are right for your needs.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.

Founded in 1988, Infrared Consulting Services (ICS) provides professional infrared electrical, NDT and building envelope inspection services nationwide.